Perhaps your home or business belongs to the 84.2% with access to differentiated municipal waste collection in Costa Rica. If so, then you periodically hand over clean, dry, and separated materials for recycling: plastic, paper, cardboard, glass, aluminum, tin, and perhaps even electronic waste.

But what happens next?

“I would like to know what the municipality and the collection centers do with recycling. Do they really recycle it? Or do they just end up throwing it out?“ asked a resident of Montes de Oca, San José, in our National Recycling Survey.

According to the 2022 report State of Comprehensive Waste Management in Costa Rica, the almost 64,000 tons of ordinary recoverable waste that was collected and recycled in 2021 does include “ordinary recoverable waste that was rejected, mainly because it was not clean, dry or did not have a market.” The data presented in this report from the Ministry of Health indicates that, in 2021, materials rejected at private and municipal recoverable waste recovery centers—whether they recycle, export, or just separate—added up to 1,222 tons.

In other words, the fears expressed by that Montes de Oca resident and others in our survey could be justified. The material that we hand over to collectors and recycling centers to be recycled could end up in a landfill, or be sent for co-processing—that is, facilities that use waste as fuel to produce energy.

Of all the possible recoverable waste produced in 2021 in Costa Rica—plastic, paper, cardboard, glass, aluminum, tin, electronic waste and others)—the most common material handed over for recycling was aluminum and tin, 32.76%, and paper and cardboard, 32.63%. This was followed by certain plastic products with 12.20%, and glass, with 12.19%.

But how much of all these materials are used within the country to develop some new product—to close the circle of the internal circular economy?

According to the most recent publication from the Ministry of Health on this subject (National Policy for Comprehensive Waste Management 2023-2033 and National Plan for Comprehensive Waste Management 2023-2028), had “455 active authorized [waste] managers as of May 15, 2023,” responsible for “collection, transportation, storage, preparation for recovery, valuation, export, import, treatment and final disposal” of recyclable materials. Of these, 85 are registered as exporters.

“Of the total non-hazardous waste, 91.3% was recovered and 8.5% was exported. As for special handling waste, 90% was exported and only 9.8% was valued in the country,” the document says. “With hazardous waste, 29.8% was recovered in the country, 24.3% was treated and 46% was exported.”

This means that of the materials for recycling that are separated in homes and businesses, a part is being valued or processed in Costa Rica, but another is exported to be processed and valued outside our borders.

Producing in Costa Rica from recyclable materials

People who prepare material for recycling in their homes and offices may feel like they are opening a Pandora’s box when they try to separate it. Some materials are easier to figure out: glass on one side, paper and cardboard on the other, aluminum cans over there. But beyond that there is always a lot of uncertainty about what can be recycled.

One of the questions in our National Recycling Survey asked people to tell us what they think is recyclable. More than 90% of people surveyed agree that cardboard, plastic soda bottles, glass and aluminum cans are recyclable. Between 80 and 90% of people agree that you can recycle white paper (89%), TetraPak (87%), and plastic lids (85%). However, all of these materials are recyclable only if delivered clean and dry. What’s more, many others on the list that fewer people selected, such as plastic bags (72%), are also recyclable.

The problem is that not all recycling processes are economically viable for processing entities—or not all of them can be recycled in Costa Rica, so their export and sale abroad is not economically viable either.

The issue is complex, because “can this be recycled?” is not the only question that matters. We also have to ask what can be recycled in Costa Rica. For example, aluminum and tin are materials that can be recycled completely, many times over, but these processes of transforming post-consumer aluminum or tin into new products do not occur in Costa Rica. That means that when you separate your aluminum cans for recycling, they, along with certain other recyclables, will not be recycled here. Instead, they are prepared for export by authorized managers. This export process has its own ecological impact.

This doesn’t mean that people should stop separating recyclable materials that are not being processed in Costa Rica. On the contrary, separating these materials is still the best option. It keeps them from ending up in landfills or open-air dumps. What’s more, processing these materials, even when it’s just for export, generates jobs and profits that help the country’s economy.

But wouldn’t it be better if this type of industry were promoted in Costa Rica? How much better would it be for the country’s economy to export finished products, and not just post-consumer material for recycling?

That’s the case for many recycling processes that are already carried out in Costa Rica. Recovering these materials is not only profitable, but makes Costa Rica a producer.

Let’s take a look.

Glass, cardboard, paper, and TetraBrik: the old and the new

One of those companies is VICAL, or Grupo Vidriero Centroamericano, which has been processing post-consumer glass at its plant in Taras de Cartago for more than 45 years and then producing new glass containers. According to Luis Alejandro Conejo Araya, Coordinator of VICAL’s Recycling Department, the company processed an average of 1,931 tons of cullet—the term for recyclable glass—per month in 2023. So far in 2024, they are already recovering more than 2,000 tons per month.

“Right now, our cullet comes from bottlers, structural glass importers, and Recovery, Separation and Marketing Centers for municipal and private materials,” Luis Alejandro says, explaining where the material comes from. VICAL buys the material and also pays for transportation.

Another material that is also recycled within Costa Rica is cardboard and paper. The Empaques Santa Ana company is a leader in this industry, producing kraft paper from recyclable materials.

“At the beginning of 1987, when Empaques Santa Ana was founded, it manufactured corrugated cardboard boxes,” explains Collection Manager Brayan Molina Alfaro. “Once the corrugator was consolidated, the business owners saw an opportunity to carry out vertical integration by installing a paper mill, and that given the conditions of the country, the correct thing to do was to install one that would process recycled material. Nowadays, in addition to kraft paper liners and materials for the corrugated sector, most of our paper is used to make corner pieces and tubes.”

Brayan explains that the company can process more than 95,000 metric tons annually—that is, about 7,900 tons per month. “Our strategic plan establishes an annual growth of no less than 5% in the manufacture of recycled paper,” he adds.

In June 2023, Empaques Santa Ana ventured into TetraPak recycling.

“We’re now processing 80 metric tons each month [from TetraPak],” explains Brayan. “The fiber recovered from TetraPak containers is incorporated into cellulose pulp for the production of recycled kraft paper.”

Brayan says that these materials come from a wide range of sources, from companies dedicated to producing boxes, to post-consumer material that comes from municipalities, collection centers, authorized managers and private companies. The material is purchased locally. He says that the price depends on what the national and international market dictates at the time.

“Empaques Santa Ana’s business model is based on the circular economy, which encompasses sustainability not only from an environmental perspective, but also from a social and economic perspective,” Brayan says when asked about the impact that the company achieves through recycling. “Within the company, direct employment is provided to approximately 350 people. However, indirectly, by involving collectors, transporters, base recoverers, and other participants in this value chain, job opportunities are generated for around 1,000 people. These include people in situations of social vulnerability, such as unhoused people and women from rural areas.

“This model not only promotes the decarbonization of the economy, but also promotes the generation of decent and green jobs, thus strengthening our commitment to sustainable development,” he adds.

Batteries: innovation

A novel example of processing recyclable materials in Costa Rica is the company Fortech Circular, which works with Electrical and Electronic Equipment Waste (described in Spanish with the initials WEEE). Fortech recently inaugurated Costa Rica’s first lithium battery treatment plant, according to María Fernanda Camacho, commercial manager of Fortech Circular.

“Lithium batteries are waste that can be found in electronic devices and all rechargeable devices, as well as in electric mobility and micromobility,” says María Fernanda. “The estimate is that in Costa Rica around 1,500 tons of lithium batteries are generated per year—an alarming figure, if they are not managed correctly.

“[At Fortech] the batteries are transformed, and 98% of the components [active materials of cathode, aluminum, copper and plastic] are recovered,” she adds. “They are returned to the foreign market and producers to create new materials with these components. We call this process urban mining.”

Corporate video shared with El Colectivo 506 by Fortech.

In addition to lithium batteries, Fortech processes hazardous waste (solid and liquid), special handling waste (electronic equipment, batteries, metals), and non-ferrous waste (with aluminum, copper and other metal components). Developing all of these processes took five years of research and technological development.

María Fernanda explained that today, Fortech processes the “equivalent of 300,000 cell phone batteries, 50,000 laptop batteries, or 100 electric vehicle batteries.”

Plastic: a complex world

The problem with recycling plastic is that each type of plastic has particular characteristics that require different types of processing for recycling. In other words, we can crush all types of plastics together, but we cannot necessarily convert that heterogeneous mass of pieces of plastics for a specific new product.

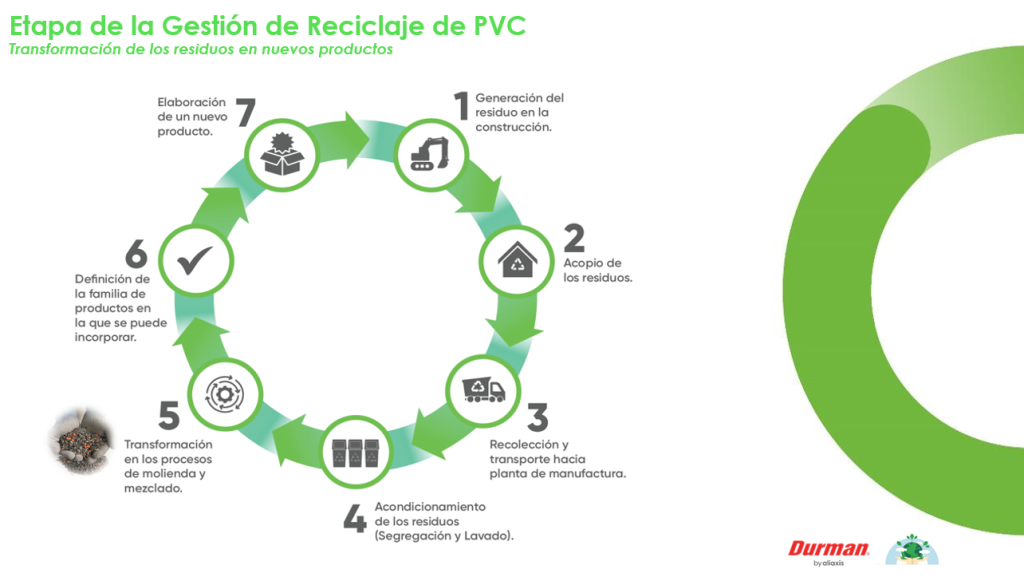

Here’s an example. To recycle PVC, or plastic #3, into new finished products, it is essential that it is not mixed with anything else. This plastic must also be handled according to its specific manufacturing process. Because of this, it has not been widely recycled in Costa Rica and the region.

However, since 2023, the Durman company, through its Durman + Sustainable management program, has begun incorporating recyclable PVC into its final products at its processing plant in Costa Rica.

“In 2023, we collected a little more than 18 tons [of recyclable PVC],” explains Silvia Quesada, SO and Environment Manager for Durman.

Silvia explains that the materials Durman is recycling are leftovers from construction or remodeling projects that would normally be sent to the landfill.

“The PVC waste we manage comes from the construction sector, mostly from our clients. Starting this past December, we opened up the possibility of not restricting this only to our own products. We have been working with public-private alliances to be able to open recovery points nationwide,” Silvia adds, explaining that part of that process is determining how much they could start paying for this material.

To carry out this process, Durman has created a selection and washing process in its collection center. This has allowed them to hire and train two people to select the different PVC materials to be used.

“This year [2024], our goal is to recover twice as much as the previous year at the Costa Rica plant,” she says. “The Durman + Sustainable management program is the first of our plants in Latin America, and we have shared best practices in the region so that other plants can adjust it to their local needs.”

More and more companies in Costa Rica have established production processes to convert plastic waste into new finished products. That’s the case with Durman. It’s manufacturing PVC pipe, rather than simply producing crushed or pelletized plastic for export to other parts of the country. world.

Another example of these companies is PRODUCOL, located in Pavas, San José. Since 2002, this company has been producing plastic wood from plastics #2, #4 and #5. Those plastics include laminated plastics found in cookie packaging that consist of a mixture of these three polymers.

Today, PRODUCOL processes 22 tons per month of plastic for recycling. It buys these materials mostly from suppliers that deliver clean, separated materials, or it receives the materials through alliances with companies and organizations such as ProParques or eCoins. Margarita Rodríguez, Marketing and Sales Manager of PRODUCOL, explained that they can receive only material that has been carefully prepared, because they are a microbusiness (MSME) and do not have the capacity to clean, classify, and separate the plastics.

Margarita also explains that the company uses only plastics #2, #4 and #5 in order to guarantee the quality of the product and to be able to offer uniformity. Their products include not only boards, beams and posts, but structures such as platforms, benches, trash cans, playgrounds, and even custom furniture.

PRODUCOL and a large number of other companies in the country that are working to offer finished products from recycled plastic in Costa Rica are up against tough odds. Next, we’ll take a look at that struggle through the cases of PWI and Bosque Plástico.